Quality Silage Making: Specific reference to Maize Silage

By Dr. Marius Bogdan and Dr. Suyash Vardhan

Maize silage is often used in dairy cow feeding and represents 50% or more of the total content in Total Mixed Ration (TMR) in Europe, North America, Australia and Asia. Maize or corn is a very versatile plant with high growth rate, resistant and one of the most high-yielding forage crops (Roth et al., 2001).

Globally, maize is a leading cereal grown – in EU-28 maize was grown on 14.7 million hectares and maize silage acreage was 5.9 million hectares. In India, maize is the third largest crop after wheat and rice. It is being used for human consumption, fodder, and industrial applications like starch, oil, beverages, sweeteners, pharmaceutical applications, cosmetics, gums, packaging and paper industry.

Because of high palatability, important starch level, digestible NDF and protein, corn silage is the most valuable forage for ruminant livestock. Nevertheless, in order to obtain a very high quality corn silage, few critical points have to be considered.

Harvesting

Harvesting time is essential in order to achieve not only the best nutritional value, but also to reduce mould contamination risk on the field.

- Optimal cutting stage: dry matter between 30 and 35% DM. It is very important to know that drydown rate is 0.5-0.75 % per day, even higher in hot climate.

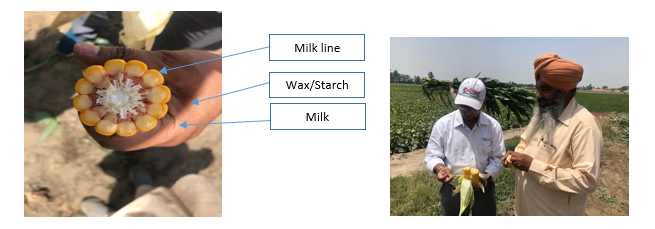

- Optimum milkline stage: ½ to ¾ (figure 1). High milk ratio means low starch content, whereas low milk ratio (dry kernel) means dry silage and therefore poor compression in silage pit.

- Length of particle: 10-15 mm or 19-22 mm if mixing wagon has a silage cutter.

- Kernels should be broken into multiple pieces and cobs should be broken into thumbnail-sized pieces or less (Roth et al., 2001).

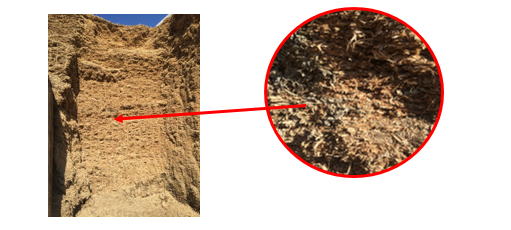

- More than 90% of kernels have to be crushed. Corn starch is the most important fermentation substrate for lactic acid bacteria. If corn kernels are not crushed, starch is not available for lactic acid bacteria, hence the fermentation will be poor, pH will not decrease enough and the consequence is mould proliferation. Also, most of uncrushed kernels will not be digested by cow and it will be eliminanted in manure (figure 2).

Figure 1. Determination of milk line, to judge the correct harvesting time for maize fodder

Figure 2. Uncrushed kernels in corn silage are eliminated undigested in the manure

Compression

Compression is the most important point at ensiling, because it minimises aerobic activity and maximises anaerobic activity.

- Layers for compression: max 30 cm.

- Use heavy tractors/tools that can apply uniform and heavy pressure (figure 3), in order to eliminate as much Oxygen as possible.

- Cover the silage every night.

- When continuing work on the second day, it is recommended to not compress the pile created the day before because this will eliminate CO₂ produced during the night. Compressing should start only after fresh corn is loaded on top of the pile.

- After last layer, continue to compress another 2-3 hours.

Figure 3. Compacting silage, 2 MT pressing weight behind heavy tractor for better compaction.

Preparation of Silage Pit and its Sealing

After Oxygen has been removed from silage it is very important to keep the air outside, so it is recommendable to use two plastic folia:

- One very thin folia, maximum 40μ thick which is in direct contact with silage and contours the forage, filling any gaps left during the packing

- Top of the silage has to be covered with a 150-200μ plastic folia for protection against water, rodents and birds

Figure 4: Preparation of Silage Bunker.

Fermentation

Upon silage pit sealing, a chain of reactions starts, the most important ones being anaerobic fermentation:

- Phase I (1-2 days) – in this phase the plants continue their respiration and, as a result of this activity CO₂ is being produced. Inside the silage mass the temperature starts to raise above 20°C and the pH is around 6-6.5.

- Phase II (1-3 days) – anaerobic fermentation starts; acetic acid, lactic acid and ethanol are produced and temperature reaches 30-32°C. The pH decreases to 5 and lactic acid bacteria start flourishing. This is also known as hetero-fermentative phase. At times, if natural occurring bacteria is more than 10,000 CFU/g, it may limit the growth of lactic acid bacteria, especially of bacterial inoculants.

- Phase III (3-5 days) – now the fermentation is almost exclusively lactic, pH drops to 4 and, by the end of this phase silage mass starts to cool down. This is also known as homo-fermentative phase. Under tropical climate, it is important to achieve pH 4-5 early in order to prevent hot fermentation in silage, which makes it favourable for mould and yeast to grow within silage.

- Phase IV (15-21 days) – all kind of fermentations are almost shut down, pH is stabilized at around 4 and the temperature inside the silage mass should be more or less the same as the environment temperature (maximum 10-15°C above environment temperature)

Figure 5: Dr Marius sharing Silage preservation technique with dairy farm advisors

After 45 days the silage pit may be opened, however it may be opened at around 30 days, if silage stabilizers have been used. It is extremely important that when opening the silage pit to analyze the silage quality. Few parameters, if correctly interpreted, reflect not only the fermentation quality, but also the nutritive values of the silage (table 1).

Table 1. Corn silage parameters

|

Parameters |

Minim |

Maxim |

|

|

Dry Matter, % |

27 |

37 |

|

|

Crude Protein, % DM |

7 |

- |

|

|

NPN, % DM |

< 5 |

||

|

Starch, % DM |

25 |

- |

|

|

ME, MJ/kg DM |

> 8 |

||

|

NEL, MJ/kg DM |

> 6 |

||

|

Ash, % DM |

3 |

5 |

|

|

ADF, % DM |

20 |

26 |

|

|

NDF, % DM |

40 |

45 |

|

|

Sugar, % DM |

2 |

4 |

|

|

Fat, % DM |

3 |

5 |

|

|

Lactic Acid, % DM |

3 |

7 |

|

|

Acetic Acid, % DM |

< 2 |

||

|

Butyric Acid, % DM |

< 0,1 |

||

|

Propionic Acid, % DM |

< 1 |

||

|

Ethanol, % DM |

1 |

3 |

|

|

pH |

3,8 |

4,5 |

|

Nutrient values show the nutritive quality of the silage, whereas organic acids levels and pH reflect quality of fermentation and silage mass stability.

A low pH indicates that the silage is stable and moulds cannot further develop. High pH, over 4.5 can be a result of a dry silage (over 50% dry matter), Clostridia fermentation, extreme mould contamination, or high level of ammonia.

Lactic acid is an important organic acid for good silage because it is a strong acid, with low dissociation constant (pKa=3.86). High level of lactic acid means that good fermentation occurred and the silage is stable, while low lactic acid content is a result of high dry matter content or Clostridia fermentation. Lactic acid is the most efficient preservative of corn silage. Regardless what additives we are using (e.g. silage inoculants or mixture of organic acids), the outcome is the same: pH starts to drop, lactic acid bacteria prevail as pH decreases, so at the end of the day lactic acid becomes the most prevalent acid in the silage pit. Experts recommend a mixture of organic acids containing Lactic acid, Sorbic acid, Propionic acid and its stable salts exactly for this reason.

High levels of acetic acid can be encountered in very wet silages (below 25% dry matter), in silages that were slow compressed or bad covered or in silages treated with ammonia, which raises pH and this can lead to dry matter intake limitations.

High level of butyric acid, over 0.5% in dry matter shows that a Clostridia fermentation has undergone. This situation might occur when soil is mixed with crop during harvest. Silage with high butyric acid level will have low nutritive value and high ADF and NDF.

Usually, propionic acid concentration in corn silage is less the 1%, but when dry matter is around 35-40%, this organic acid is almost undetectable. Because propionic acid is a good silage stabilizer and energy source, a low propionic acid silage can be treated with Propionic acid or its salt based organic acid additives or biological additives such as silage inoculants. Inoculants can be used following its specific composition, environmental and climatic condition and inoculant’s specificity of the crop and manufacturers storage and usage specifications.

Under conditions when extremely wet or dry silages are prepared, or when compressing is poor and when silage pit coverage is improper, the yeast or mould activity restarts and second fermentation of silage occurs. Visible indications of such a silage damage are high pH, increasing silage mass temperature, high ethanol level, high butyric acid level, odour and colour modifications. Usually silage becomes yellowish because of Maillard reaction, but also can have dark brown, black or red spots because mould activity and bad, acidic odour can be detected.

Though there are different opinions for the usage of the silage additives for effective preservation of silage, few important aspects needs to be taken under consideration:

- Dry matter content and crop type: Many inoculants are crop specific and require effective storage specification, from refrigeration to cool and dry storage specifications. Choice of bacterial strain and its adaptability in specific crop should be considered

- Climatic condition at the time of ensiling: As in tropical climate temperature remains high, it is important to choose additive considering the hot and humid condition. It is important to bring pH down to 4-5 to prevent hot fermentation and provide anaerobic condition to ensiled material.

- Wet Silage (when harvested under high moisture condition or rainy season), needs adequate precaution, as it is prone to low aerobic stability and less compaction.

- Dilution of silage additive needs to be such that it leads to high Aw activity in ensiled material, resulting in water pockets in ensiled material.

- Conventional methods like incorporation of salt, urea, molasses needs to be reviewed by silage experts, as it is quite specific to the ensiled material with clear objective of the preservation requirements. Incorporation of high amount of Salt and Ammonia, may not allow pH to drop down to desirable level and as Molasses quality varies a lot, it may not be fit for silage.

- Addition of enzymes as silage preservative is usually targeted towards mobilization of sugar content from starch, but needs to be evaluated, on the basis of its requirement and its choice as per the crop type.

- Aerobic fermentation inhibitors (FI) like Selko TMR, under hot and humid climate works well provided its incorporation and composition fills in the requirement of silage preservation. FI, with blend of organic acid, rich in lactic acid, propionic acid, sorbic acid and propionate salts helps in reducing pH quickly, control water activity in ensiled material and aerobic stability of the fodder kept under preservation, without specificity of the Crop type.

It is advised that use of silage additives can improve shelf life of the silage in bunkers and bales. Main emphasis needs to be given on the quality of silage manufacturing which includes all management aspects starting from - sowing in the right season, harvesting at the right DM, proper wilting and filling in the Bunkers and Bales, right pressing and compaction, proper packing and face management while opening for feeding. Use of Silage additives does not ensure better preservation quality if silage making management is poor.

One of the most common reasons of second fermentation is silage face management since exposure to air is huge and constant in this area (figure 6).

Figure 6. Silage mold spoilage because of second fermentation

In order to avoid mould in the silage, there are few actions that have to be taken, both before and after ensiling.

Before ensiling:

- Start harvesting at right corn maturity (milk line at ½ - ¾)

- Check the whole plant moisture: 63 – 73%

- Chop corn silage at 10-15 mm

- Perform a very good compression of silage mass

- Close silage pit as soon as possible and seal it with two layers of plastic folia

- For better fermentation, treat silage with silage inoculants (mixture of homo- or hetero-fermentative lactic bacteria). However, these bacteria, even though can be effective in regulating lactic fermentation, they do not survive in highly acidic silage (Jones et al., 2004)

- For better fermentation and silage stabilization, treat silage with fermentation inhibitors. These products are mixtures of organic acids, usually propionic acid, sorbic acid, benzoic acid. Organic acids lower silage pH and therefore are very effective in inhibiting molds and yeasts growth

After ensiling:

- Ensure a contact area with the air as low as possible after silage removal for feeding

- Ensure a feeding speed of 1.5 m/week. If this speed cannot be managed, the contact surface can be treated with silage stabilizers that contain organic acids (i.e. propionic, sorbic or benzoic acid).

- Regardless how good the silo is managed, open surface is exposed to Oxygen (figure 7), so an undesirable fermentation can start at any time, especially under hot climate circumstances

Figure 7. Exposed surface of the silage leads to second fermentation

Second fermentation after silage pit opening is very dangerous, as mycotoxin production can occur, toxins being the mould’s response against stressful situations. Mycotoxin’s harmful potential is reflected in three components:

- TMR organoleptic qualities – some moulds damage silage content, reducing feed intake and this leads to low milk production (Penicillium spp., Mucor spp., Rhizopus spp. etc.)

- Animal health – some have direct effect on animal health through their toxins, producing important disorders at different levels: rumen (Fumonisin, Patulin), respiratory tract (Ochratoxin), digestive system (T-2, DON) or in reproduction (Zearalenone). In India, major presence of Aflatoxin B1 has been detected in majority of raw material as well-finished feed samples in lab analysis.

- Human health – some mycotoxins can be transferred from silage to cow and further in milk, threatening human health. One of the most important toxin is aflatoxin, which is quite a common mycotoxins produced by Aspergillus spp. especially in corn silage under hot climate environment. There is an important transfer rate of aflatoxin metabolites in milk (Aflatoxin M1 and M2), ranging between 1% and 6% (Diaz et al., 2004).

It is therefore very important to produce a high quality silage, because a bad maize silage represents a limiting factor for dry matter intake. However, even if moulds are not spoiling organoleptic characteristics of the TMR, the insidious mycotoxins will impede cow metabolism or, worst; will be consumed by people via animal products.

Please get in touch with your local Trouw Nutrition representative or contact us at customercareindia@trouwnutrition.com

References available on request.