Heat Stress and Egg Production: How High Temperatures Affects Layers?

Heat stress is a major challenge in layer production, especially during the hot summer months. It occurs when birds face difficulty in achieving a balance between body heat production and heat loss. This imbalance can lead to several health issues and production losses.

⬆ Mortality

⬇ Gut health

⬇ Body weight

⬇ Immunity

⬇ Egg weight

⬇ Albumin height

⬇ Feed intake

⬆ CFCR

⬇ Egg production.

⬇ Egg shell quality

Mitigating strategies to reduce heat stress

1. Drinker system management -

- Availability of drinking water

- Sufficient water flow (> 70 ml/minute/nipple drinker)

- Sufficient drinker space

- Additional drinkers for floor-reared flocks

- Keeping water temperature below 25°C

- Flushing water lines during the afternoon

- Vitamin and electrolyte supplements in the drinking water

- Installation of water tank inside the shed

- Pandhal and whitewash for water tank which is outside

- Underground water pipeline

- Covering of pipeline which is not underground

2. Ventilation and Farm management

- Do not disturb the birds during the hottest time of the day

- Adjust work schedules and lighting programs

- Management practices should be done in the early morning hours (beak trimming, transfer and vaccinations)

- Use foggers and misters – Adjust time on the basis of temperature and humidity.

- Using roof sprinklers during times of extremely high temperature

- Do not run the feeders during the hottest time of the day

- Increase the movement of air in open houses with stir fans - minimum velocity of 1.8–2.0 meters/ second

- Do not overstock cages

- Transport birds early in the morning or at night.

3. Lighting Program

- Adjust the lighting program to provide more morning light hours - to encourage feed consumption

- Use a midnight feeding of 1–2 hours to provide an additional feeding

- Lower the intensity of light during the hottest time - to reduce bird activity.

4. Nutritional Management

- Avoid feeding times during hot periods of the day

- Feed distribution at early morning (1/3) & evening time (2/3)

- Feed type – mash /crumble - With crumble diets, presentation of large particle limestone

- Feed should be made denser with nutrients, vitamins, and minerals

- Usage of vegetable or highly digestible protein sources

- Formulate to digestible amino acid targets

- Usage of Fats or oils to adjust feed energy

- Vit. C , Vit. E and betaine

- Feed should be denser with nutrients, vitamins, and minerals

- Use of Maduramycin as an anticoccidials

- Dietary electrolyte balance (molar equivalence of Na+ + K+ – Cl-) - <250 mEq/kg

- Intellibond ZMC

What are phytogenics and how do they work in poultry nutrition?

Phytogenics are bioactive components from plants that function as defense mechanisms or signaling compounds. Due to co-evolution, phytogenics can have physiological effects on animals through acting upon molecular receptors along the gastrointestinal tract.

These receptors are conserved across species and are functionally important; when activated they modulate animal immunity, physiology, metabolism, etc. When used at the right dosage, phytogenics can be deployed as management tools to support the animal in combating many of the challenges faced in livestock production systems

What is the importance of minerals for poultry health & production?

Minerals are crucial for metabolic functions of poultry which helps to support growth & development, enzyme activities, immune functions, health & the reproductive performance during poultry production.

Supplementation of adequate quantity of minerals is critical because large number of feed ingredient used in poultry feed are not having enough mineral composition & bioavailability to recure from the mineral losses during egg and meat production, growth as well as excretion.

Mineral deficiency challenges lead to poor production & health of the birds. That’s why it is advised by nutritionist to add require amount of both major & trace minerals in all phases of poultry feed.

In the current scenario of the uncertain prices and availability of raw materials, what factors should be considered during grain storage? Does grain treatment help grain storage for longer intervals?

Storage of grains in silos has become important in today’s scenario for greater time lengths due to uncertainties of bad crop affecting unavailability, high prices of raw material etc. The major alterations to stored grain that can be attributed to fungal invasion include discoloration of either the germ or embryo or the entire seed or kernel, mustiness, potential production of harmful toxins, biochemical changes within the grain, and loss in weight and nutritive value. These changes may occur before the mold becomes visible to the naked eye. Fungi are common throughout nature; factors like moisture content of grain, temperature and length of storage plays a part in mold development.

Nutrient loss due to molds is captured in the table:

|

Material |

ME(Kcal/Kg) |

CP(%) |

Fat(%) |

|

Good Corn |

3.410 |

8.9 |

4.0 |

|

Moldy Corn |

3.252 |

8.3 |

1.5 |

|

Nutrient loss |

158 |

0.6 |

2.5 |

|

Nutrient loss (%) |

4.6 |

6.7 |

62.5 |

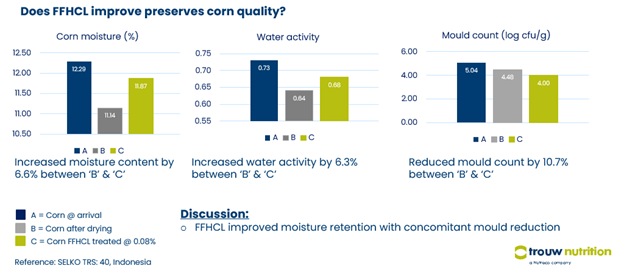

Treatment with Fylax Forte HC Liq prolongs shelf life of corn, grain, feed ingredients by reducing mould risk by preventing moisture loss , maintain less water activity and reducing mould count .

How does moisture affect feed quality?

Moisture significantly impacts feed quality, particularly when water absorption is uneven or incomplete. This issue can result in various problems including low pellet quality, nutrient segregation, and spoilage. Both high and low moisture content in feed present challenges. High moisture levels decrease throughput, elevate energy demands during pellet-making processes, promote feed spoilage, and yield dense, brittle pellets. Therefore, maintaining optimal moisture levels is essential to ensure consistent, high-quality feed production.

Why is moisture loss problemsatic in fed?

Moisture loss is problematic for producers and end users, significantly impacting nutrient distribution, inventory loss, feed costs, yield, and profitability.

What are trace minerals?

Trace minerals are metal elements that are essential to optimize animal health, well-being, and performance. Unfortunately, raw materials within the feed often do not contain enough to fulfil the animal’s nutritional requirement. Therefore, different minerals are commonly supplemented in animal feed, such as copper, zinc, magnesium, iron, selenium etc.

Why are trace minerals important?

In the intricate world of animal nutrition, the significance of supplementing trace elements like Zinc (Zn), Copper (Cu), Manganese (Mn), Iron (Fe), Iodine (I), and Selenium (Se) cannot be overstated. These elements play a pivotal role in ensuring the health and performance of livestock.

What is antimicrobial resistance in poultry?

Antimicrobial resistance (AMR) in poultry refers to bacteria in poultry becoming resistant to antibiotics, reducing the effectiveness of these drugs in treating infections. This can pose health risks to both poultry and humans consuming poultry products.

How do you manage mycotoxins?

Mycotoxins in feed can be managed through strategies such as proper storage conditions, regular testing of feed ingredients, using mycotoxin binders or adsorbents, and implementing good agricultural and manufacturing practices to prevent mold growth in crops and during feed processing.

What are the most common mycotoxins in poultry?

Most common mycotoxins in poultry – aflatoxin B1 (AFB1), ochratoxin A (OTA), T-2 toxin, DON, fumonisin B1 (FB1) and zearalenone (ZEN) – and “emerging” mycotoxins

What are mycotoxins?

Mycotoxins are secondary metabolites produced by moulds that can infest raw materials and poultry feeds. They can be produced while crops are growing in the fields and at various stages of raw material storage and transportation.

How do you control and prevent mycotoxins?

Mycotoxins can be controlled and prevented by implementing good agricultural practices, proper storage conditions, regular monitoring and testing of feed ingredients, using mycotoxin binders or adsorbents, and employing effective feed management techniques.

What is a premix in cattle feed?

A premix in cattle feed is a concentrated mixture of vitamins, minerals, and other essential nutrients added to the base feed ingredients to ensure the proper balance of nutrients in the animal's diet.

What is a premix in poultry feed?

In poultry feed, a premix refers to a concentrated blend of vitamins, minerals, amino acids, and other essential nutrients added to the base feed ingredients. This ensures that the feed provides all the necessary nutrients in the correct proportions to support the growth, health, and productivity of poultry birds.

What are poultry feed additives?

Poultry feed additives are substances added to poultry feed to improve the quality, nutritional value, health, and performance of birds. They include vitamins, minerals, amino acids, enzymes, probiotics, prebiotics, antibiotics, and growth promoters

What are the best organic trace minerals in poultry?

The best organic trace minerals for poultry include sources such as organic selenium, zinc, copper, and manganese. These forms are more readily absorbed and utilized by poultry compared to inorganic sources.

What are toxin binders?

A toxin binder is a substance added to animal feed to adsorb or neutralize toxins, such as mycotoxins, present in the feed, preventing their absorption by the animal and minimizing their negative effects on health and performance.

What is toxin binder for poultry?

A toxin binder for poultry is a feed additive that helps to adsorb or neutralize toxins, such as mycotoxins, present in the feed, reducing their harmful effects on poultry health and performance.

What is the role of a mycotoxin adsorbent?

Adsorbents, or binders can be very effective for certain mycotoxins, but not all. The physiological complexity in the gut may compromise binding efficacy and, therefore, it is not wise to rely on a toxin binder alone.

Can I rely solely on mycotoxin binders?

We recommend that you combine binders with other functional ingredients that can mitigate the toxicity of mycotoxins. An integrated binding and remediation strategy can help minimize the negative impact of mycotoxins on animal health and performance. TOXO-XL contains ingredients that support this combined strategy.

I use mould inhibitors to prevent mycotoxins – is that enough?

Mould control is important, but not alone sufficient to prevent mycotoxin occurrence. Since mycotoxins are metabolites of moulds, they can be produced even while crops are growing in the field. Once present, most mycotoxins cannot be removed through acidification or heating and other strategies are needed to prevent them from impacting animal performance. So, even when moulds are removed at any step of the feed production chain, mycotoxins that were already present will continue to pose a risk.

What are phytogenics?

Phytogenics are bioactive components that function as defence mechanisms or signalling compounds within plants. Due to co-evolution, phytogenics can have physiological effects on animals by acting upon molecular receptors along the gastrointestinal tract.

What actions can I take to prepare the storage silos?

Before storing grains, make sure that the storage area is clean and free from any debris, dirt, insects, etc. This is particularly important when a previous batch of grain stored in the silo was contaminated. It may be necessary to fumigate the area before storing new grains.

While grains are best stored between 10ᵒ C and 15ᵒ C, realistically, this is not always possible. Nevertheless, it is important to know that temperatures above 30ᵒ C significantly increase the spoilage rate. Proper aeration and ventilation need to be in place before grains are stored.

Perhaps an obvious precaution is the importance of rotating grains, though in practice it is not always as easy as it seems, especially in flat storage facilities. Older stock needs to be used up before new grains are added.

Finally, I would always advise handling grains with care. Every time grains are handled or transported, there is a risk of damaging the outer skins, which leaves the delicate inner core unprotected against invading microbes or pests. When there is a lot of grain damage, it is advisable to treat the grains with effective organic acid solutions that also help prevent recontamination further along the feed production process.

How can microbial load and mycotoxins be reduced in the intake pit?

To determine if treatment of grains is needed, and which treatment is best, it is important to be aware of the microbial load upon receipt of the grains. This is especially important since microbes such as moulds can already negatively impact quality without being visible and can only be discovered through sample analysis.

Preservation with a synergistic blend of specific organic acids drastically reduces microbial load and helps protect against further deterioration and recontamination. This will help safeguard the nutritional value and extend the shelf life of your grains.

However, moulds that were already present in the grain could have already excreted mycotoxins. These toxins cannot be deactivated by organic acids (or even heat treatment in most cases) and need specific mycotoxin mitigation agents to prevent a negative impact on animal health and performance.

Once grains are stored, how can quality be maintained?

Once grains are stored, monitoring becomes even more important to understand their quality and its possible degradation. Constant monitoring through temperature and moisture sensors in the silos help to detect early signs of microbial development so that measures can be taken. A spike in temperature, for example, is a clear indication that you need to adjust the ventilation or aeration.

In addition to monitoring with sensors, I would recommend that you take samples at different parts of the storage area to allow for a clear picture of the grain conditions. Look for signs of spoilage, such as mould growth, discolouration, a musty smell, or evidence of insect or rodent infestation. If there are clear indications of microbe development or pests, you may need to treat the stored grains. This is usually done by spraying the grains with organic acid blends, such as Fylax Grain, while they are on the transportation line to another storage silo.

What is the contribution of supplies to the carbon footprint of a dairy farm?

Out of the total carbon footprint of a dairy farm, about 27% is coming from on-farm supply sources. Dairy feed is an important on-farm supply. The dairy feed industry should therefore try to reduce the carbon footprint for producing the feed they supply to dairy farmers.

How can dairy feed producers reduce the carbon footprint of the feed they produce?

There are several ways a feed producer can reduce the carbon footprint of the feed they produce. One option would be to be more efficient with energy or to use renewable energy sources. Alternatively, dairy feed producers can use at the carbon footprint of the ingredients they use in their feeds.

How can dairy farmers increase feed efficiency on their farms?

A number of factors that have an impact on feed efficiency of dairy cattle were listed during the presentation. Out of those, the most important are digestibility of feed, days in milk, somatic cell count and sub-acute rumen acidosis.

Is there a correlation between digestibility of fibre and milk production?

Research by Oba et al. in dairy cows has shown that each one point difference in NDF digestibility represents 0.25 to 0.3 kg of daily Energy Corrected milk production.

Can adding protected amino acids result in an increase of dry matter intake in dairy cows?

We know that an increase in RDP or RUP will lead to an increase of dry matter intake of dairy cows. It is questionable if adding protected amino acids also will.

At what environmental temperature are cattle at risk for heat stress?

The risk for heat stress is not only depending on environmental temperature but also on relative humidity. Both are combined in the Temperature Heat Index (THI). Problems can occur if the THI is above 72, which could already happen at an environmental temperature of 15 °C.

Why does heat stress in dairy cows result in loss of production?

Heat stress results in a reduction of dry matter intake which explains about 50% of the reduction of milk production. Next to that, heat stress causes “leaky gut” which leads to systemic immune activation. Energy used by the immune system is no longer available for milk production.

How can heat stress in cows be managed?

Managing heat stress in dairy cows requires a comprehensive approach. The negative effects on gut health can be mitigated by using IntelliBond instead of sulphates and by feeding Selko LactiBute which improves hindgut health.

What are the signs of heat stress in dairy cows?

Clinical signs of heat stress in cattle are:

- Panting

- Drooling

- Milk leakage

- A drop in milk production

- Standing up for long periods of time

Why are problems with mycotoxins in dairy cows so difficult to recognize?

Firstly, contamination of feed materials with mycotoxins is usually not visible, so mould or mycotoxin analysis is required. Secondly, there are hundreds of different mycotoxins that can cause problems in cattle, as a result, symptoms are often atypical.

What are typical symptoms of contamination with mycotoxins?

In case of contamination of feed with aflatoxins, aflatoxin M1 levels in milk increase above the tolerance level, leading to rejection. Symptoms caused by mycotoxins are mainly related to poor rumen fermentation, systemic immune activation leading to poor immunity, hormonal imbalance and sometimes liver and kidney toxicity, all leading to poor health, performance and reproduction.

How can problems with mycotoxins be prevented?

Reducing the risk of contamination of dairy feed with mycotoxins requires a holistic approach. Contamination can not always be prevented completely. Toxin binders for dairy feed should not just neutralize toxins, they should also improve gut barrier function and reduce systemic inflammation, thus mitigated the negative effects of the mycotoxin challenges on dairy milk production.

How can protected B Vitamins support cattle performance?

With modern, high, producing dairy cattle a sufficient supply of B vitamins to the intestine, based on feed and microbial production, is not guaranteed. Supplementation of a blend of rumen protected B vitamins supports post-absorptive metabolism.

How can trace mineral management result in better vitamin bioavailability?

Reactive trace minerals such as sulfates can have a significant negative impact on stability and bioavailability of other essential nutrients like vitamins. Copper and/or zinc can quickly accelerate oxidation of unprotected fat sources in the feed, negatively impacting the value of the fat which includes several fat-soluble vitamins.