Importance of Water Quality for Broiler Performance

By Technical Team, Trouw Nutrition South Asia

Water is the most important nutrient and essential for poultry performance. A chicken body contains 70% of water and this water content plays a key role in thermoregulation, digestion and absorption of nutrients and acts as a carrier for administration of additives, such as medication, supplements, etc. Good water quality is important as chickens consume twice as much water as feed. If the quality and quantity of water is compromised, this can negatively affect the performance, health, and welfare of poultry. Therefore, it is very important to provide clean and safe water supply for ensuring optimal broiler performance.

Figure 1: Supply of clean water to birds

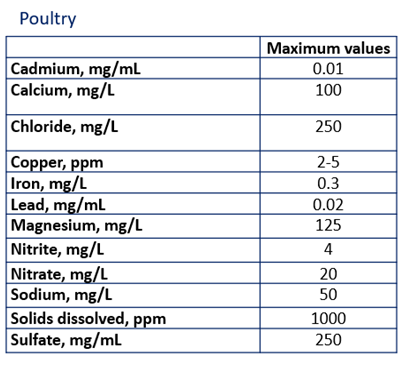

There are many factors which affect quality of water, and even impacts the water consumption in broilers. The water quality content is based on microbial, physical, and chemical parameters. Chemical parameter such as pH, hardness, and total dissolved solids (TDS) can have effect on water consumption patterns. Water quality above maximum acceptable level (Table 1 & 2) can have both high and low negatively impacts on the performance of broiler. When we analyze water samples for chemical parameters, we may observe higher level of inorganic elements such as sodium (Na), potassium (K), and chloride (Cl). This might lead to increased water consumption leading to wet droppings and poor litter conditions. Many a times, main source water and pipeline water could contain higher levels of calcium salt (hardness), high alkalinity and high level of nitrate, which need to be taken care of whilst addressing water quality.

Table 1 & 2: Water Quality Standard for Poultry

|

CFU/ml |

|

|

TVC |

1000 |

|

Enterobacteria |

<100 |

|

Total Coliform |

50 |

|

Fecal Coliform |

0 |

|

Salmonella |

0 |

Adapt from Susan Watkins, University of Arkansas Division of Agriculture.

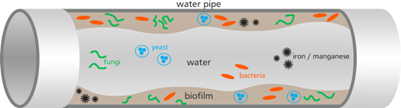

Water is carrier of microbial challenges and easily can contaminate drinking system of broiler house with biofilms (Fig. 2) which would affect the quality and quantity of water intake. Biofilms will affect bird performance consequent to the reduced effectiveness of medication & vaccination, reduced nipple flow rate, block drinking system/nipple or cause nipple leakage and increased bacterial disease mortality. E. coli is introduced into the water system, and they can survive/multiply in the biofilm.

Figure 2: Pipeline water biofilm

To overcome these situations, many customers use sanitation and acidification practices to maintain water quality for their birds.

Sanitization of water can be carried out by Chlorination, Chlorine dioxide, Hydrogen peroxide, ozone etc. Sanitation of water should be coupled with acidification, for the sanitizers to act effectively and for synergistic effect with respect to microbial control. This can be accomplished by usage of combination of free and buffered organic acids. Selko pH by Trouw Nutrition contains free and buffered organic acids which helps in maintaining good water quality along with optimal gut health conditions in birds.

Strategies for optimizing water quality:

1. Acidification with Organic acid (Selko pH)

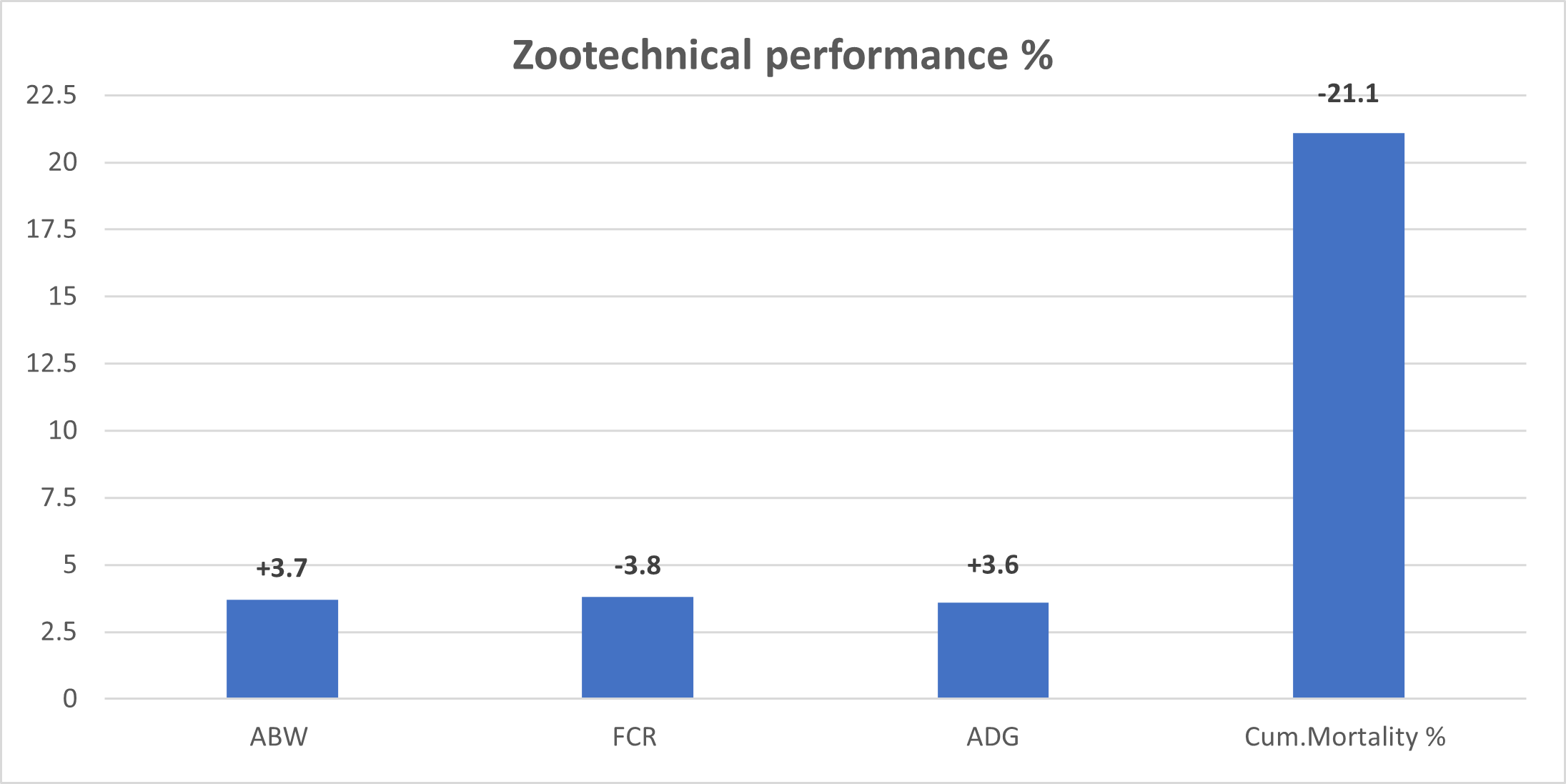

Addition of Selko®-pH in drinking water of poultry reduces and stabilizes the pH of the drinking water of animals. It supports the digestion of feed ingredients by reducing the pH in the crop and stomach. Primarily for young birds, a lower pH supports better protein digestion, as pepsin (a protease) is most active at a low pH. Less undigested protein reaching the hindgut and microbial control in the stomach results in improved performance and a healthier gut. Recently conducted local field broiler trial (39 days) against competitor product which have shown Selko pH with better birds’ performance over competitor product. (Fig. 3) and better feed digestion (Fig 4 & 5)

Figure 3: Improvement in zootechnical performance with Selko pH over other products

Water can be classified according to its alkalinity, or buffer capacity — a measurement of water's capability to neutralize acids. Knowing the water's buffer capacity helps determine the best blend (level of buffering) and the recommended application rate. The goal of using water acidifiers is to achieve an end pH of approximately 3.8 to 4.0. In water with high buffer capacity (high alkalinity), a higher inclusion rate of acidifiers is required to reach this target pH. Less buffered acidifiers can help reach the target pH at lower doses. A blend of organic acids may be worth considering when the objective is to combat biofilm and improve animal digestion, gastrointestinal microbial balance, or animal performance. Dosage is especially important. Higher amounts of a water acidifier will make more of the acid molecules available to the animal to support desired effects.

2. Pipeline cleaning and disinfection with Hydrogen peroxide

A simple and effective disinfectant usage between cycles like hydrogen peroxide will work very well in killing many bacteria and removing biofilm buildup. It also helps to prevent biofilm formation to some extent. Applying the proper concentration of hydrogen peroxide (35 % conc.) with 1-3 % water solution and allowing adequate treatment time is important to achieve desired disinfection results. Hydrogen peroxide works best for disinfection purpose and not for regular practice or as a substitute to water acidification.

3. Chlorination as maintenance during cycles

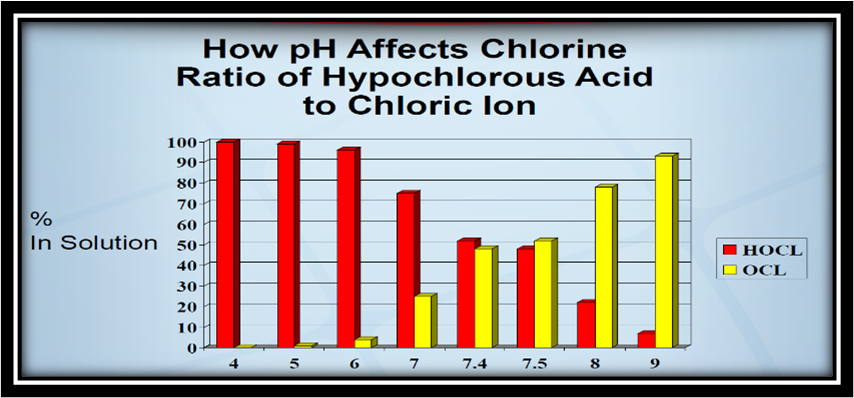

Generally, a concentration of sodium hypochlorite at 15% (100 to 150 mL/1000 L water) or chlorine dioxide applied at 0.2 to 0.4 mg/L water is recommended. The target level of residual free chlorine is important and should be between 3-5 ppm or oxidative reduction potential (ORP) in the range of 650 to 700 millivolts. Measuring the ORP in the water helps assess the balance between the water's pH and free chlorine to assure water is effectively sanitized (table 3). ORP reflects the activity of the water sanitizer as opposed to its concentration level (ppm). Chlorination becomes even more effective when combined with a proper approach to acidification. Chlorine reaction (HOCl . OCl- + H+) is pH-dependent. At a pH of 5 to 6, the chlorine species is nearly 100% hypochlorous acid (HOCl) and highly effective at killing bacteria (Fig. 6). Above pH 6, it starts to convert to the hypochlorite ion (OCl-) and acts mainly as an oxidizer. Water with a pH 7 may need to be lowered for chlorine to achieve optimal bacteria-killing efficacy.

Tables 3: Relationship between ORP and Bacterial content (Measured in water)

|

Free chlorine |

ORP |

Bacterial Count |

Pseudomonas |

|

4 |

805 |

0 |

0 |

|

4.4 |

730 |

0 |

0 |

|

4.9 |

668 |

0 |

0 |

|

2.3 |

653 |

0 |

0 |

|

1.2 |

618 |

170 |

12.400 |

|

1.2 |

296 |

640 |

1.600 |

|

0.8 |

590 |

310 |

2.400 |

|

0.7 |

480 |

15.000 |

2.400 |

Fig. 6: pH dependent effectiveness of free chlorine

Conclusion

A regular sanitation program on farm will help to improve water quality. The microbial, chemical, and physical quality of water should be monitored regularly. A good pipeline cleaning program should be in place for increasing the shelf life of pipelines and to prevent formation of biofilms. A water sanitation cum acidification protocol should be in place for improving quality of water that has been provided to birds and for optimizing their gut health conditions. Selko pH when applied in right dose in drinking water of poultry, improves the overall bird performance and can serve as an effective product in antibiotic free rearing practices as well.

For further information, kindly write to us at customercareindia@trouwnutrition.com or visit our website: www.trouwnutrition.in