Feed Safety: Leading the way to food safety

By Dr. Senjuti Kar, Program Manager (Feed Safety), TN South Asia

Feed safety is a prerequisite to food safety and human health as well as a necessity for animal health and welfare. Since feed accounts for majority of livestock production cost it is important that the feed produced is safe for the animals that consume it as well as the animal produce, like eggs, meat and milk is safe for human consumption. Animal feed plays a leading role in the global food industry, and it is the largest most important component for sustainable production of safe and affordable animal produce. In order to maintain this good quality raw materials monitored through strict quality control measures should be used for feed production. Together with this, there are various other sources of feed contamination like microbial hazards, mycotoxins, pesticides, environmental pollutants, etc.

From raw materials to final feed the four important aspects should be taken care to ensure complete feed safety.

1. Mycotoxin risk management

2. Feed Mill hygiene

3. Moisture Management

4. Microbial risk management

1. Mycotoxin risk management:

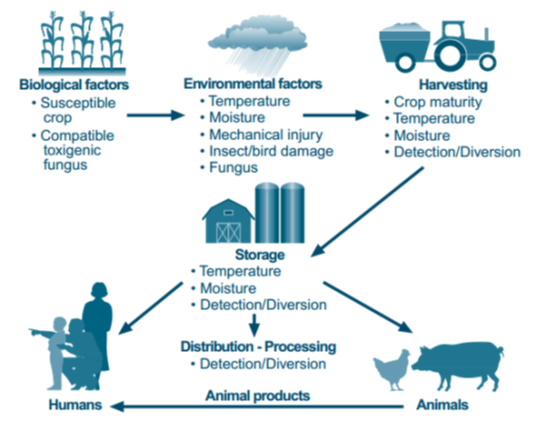

Mycotoxins are the secondary metabolites produced from toxigenic fungi recognized as major food and feed contaminants. They are a source of grave concern in food contamination, resulting in mycotoxicosis in humans and animals. Toxin production is influenced by moisture, time, temperature, and food or feed substrates. Contamination can occur throughout the food chain—from the field, during harvesting, processing, materials, preharvest contamination of mycotoxins is the most difficult part in risk management. Regarding food safety issues, food and feeds absolutely free from fungi and mycotoxins are needed everywhere to prevent health hazards and to secure the international food trade. Foods associated with fungal alterations are characterized by a low value of water activity (aW) or a low pH value, where fungi may be imposed on the colonization of bacteria and yeasts. Therefore, the main food groups contaminated by fungus are cereals and their derivatives, nuts and fruits. On the other hand, the major mycotoxin-producing fungal genera are Aspergillus, Penicillium, Fusarium and Alternaria. Nonetheless, although thousands of mycotoxins exist, the most important for public health are aflatoxins, ochratoxin, fumonisins, zearalenone, and trichothecenes.

The key to mycotoxin control is risk management taking an integrated approach rather than isolated measures. It is important that the mycotoxins present in feed are identified quickly and accurately followed by using superior quality toxin binders. A rapid mycotoxin monitoring tool will allow producers to take quick decisions with respect to the handling of mycotoxin contaminated raw materials and/or finished feed. To help identify the risk of mycotoxins in feed on the farm, Trouw Nutrition offers Mycomaster, a lateral-flow smart device that provides a reliable quantitative reading of the contamination levels in feed materials and compound feed. It enables rapid on-site, cost-effective and user-friendly analysis of six different mycotoxins: Zearalenone, Deoxynivalenol, Aflatoxins, Fumonisins, Ochratoxin and T2-HT2. This easy-to-use tool gives results within 15-30 minutes, which means that feed producers can analyze mycotoxins themselves. It can also be connected to Trouw Nutrition's global data exchange system, allowing the review of data collected from all over the globe. Good quality Mycotoxin Binders needed to be added to feed according to the risk which are specific to mycotoxin binding with little or no nutrient binding enhanced with gut health management and immunity building capacity as both gut health and immunity is compromised with multi mycotoxin challenge.

2. Feed Mill Hygiene:

As food safety and consumer awareness increases, feed hygiene has become an integral part of poultry and livestock operations – ensuring that the feed given to the animals is clean and safe. Raw materials and feed can be contaminated by pathogens that can lead to risks on health of animals and economic losses. Aside from that, the contamination in feed and ingredients is a potential risk of food safety for consumers. Since mycotoxins are produced by mould it is important that the raw materials and feed are stored properly at feed mill and farm properly. Feed mill machinery can act as strong carriers of microbial organisms and need to be effectively handled to avoid the same. Flushing of feed mill as part of maintenance program, needs to be carried out, with organic acid-based concepts, so that the production machinery is devoid of pathogenic microbes. Samples need to be collected from critical control points before and after flushing, for factual judgement of the decreased risk of (re)contamination.

3. Moisture Management:

Variations in raw materials coupled with climatic conditions can be very challenging for feed manufacturers to maintain the moisture content of animal feed. Moisture management is very important for feed producers because along with high temperature, high amount of moisture in the feed may result in growth of mould and subsequent production of mycotoxins. That is why maintaining correct and constant moisture levels in animal feed is critical in obtaining high quality feed. Also, when moisture content in animal is too less it can result in reduction in yield, increased fines, reduction in pellet durability. High temperatures along with high humidity pose optimum conditions for microbes to proliferate and reduce the quality of nutrients in animal feed. To maintain the shelf life of feed despite moisture addition, addition of mould inhibitors is of vital importance. Propionic acid has been used as a mould inhibitor and shelf-life extensor since the last 40 years. However, since it is very corrosive a blend of organic acids works better and has a broader spectrum. Trouw Nutrition’s Fylax Forte HC liquid is a liquid mould inhibitor with a synergistic blend of organic acids and surfactants.

4. Microbial risk management:

There has been several studies for microbial contamination of feed and food. Animal feed production is a complex process involving several steps during feed milling. In feed manufacturing, there are numerous opportunities to introduce microorganisms from various environmental and other sources. While most of these microorganisms are likely non-pathogenic, pathogens can also be members of feed microbial populations. In addition to fungi, several bacterial pathogens have been identified. They are believed to be associated with animal feed and include Listeria, Clostridia, pathogenic Escherichia coli, and Salmonella, as well as others that are less well characterized. These bacteria can contaminate animal carcasses at slaughter or cross-contaminate other food items, leading to human illness. Although tracing contamination to its ultimate source is difficult, several large outbreaks have been traced back to contaminated animal feed. Improvements in the safety of animal feed should include strengthening the surveillance of animal feed for bacterial contamination and integration of such surveillance with human foodborne disease surveillance systems. In managing contamination, raw materials should be strictly monitored in terms of microbial contamination like Salmonella, Enterobacteria, E. coli and moulds. Water activity (aW) is an essential parameter to be measured that influences microbial development, along with other parameters like temperature, humidity, exposure to light, air. aW is a measure of the amount of free water available in raw material or feed, that predisposes the material to microbial growth. The mould and bacterial growth can be addressed through strict quality control measures for procurement of quality raw materials, apt storage of raw materials and finished feed, and judicious inclusion of mould inhibitors and feed acidifiers. The feed acidifiers intended to be used should possess specific activity against moulds or bacteria, depending upon the pathogen to be taken care of.

Conclusion:

Foods of animal origin have an important role in a balanced diet and must be safe for human consumption. Equally important is the need for the food to be perceived as safe by the consumer. Safe food of animal origin must be free from animal pathogens that infect man and from contamination by residues. Animal feed has been identified as a critical component of food chain considering the carryover of undesirable substances such as dioxins, mycotoxins, heavy metals, pesticides, pathogens, veterinary drugs, growth promoters, specified risk material (prions), microplastics etc. from feed to food of animal origin. If carryover is not properly managed, contaminated feed can directly harm species that are sensitive to the unintended components they consume and can result in residues in foods of animal origin such as meat, milk and eggs that render them unsafe for human consumption. Hence, animal feed should be strictly monitored to rule out the presence if undesirable components. Failure to monitor the risks can lead to monetary losses to raw material producers, quality raw material supply chain, consequently deteriorating the animal health and performance; and the end product (meat, milk & eggs). Trouw Nutrition’s complete risk management programme enables to make decisions based on knowledge and data, and to use our products in the most effective way.