Feed Safety – Importance, Components and Ways to Ensure Safe Feed Production

- Feed Safety

Dr. Sabiha Kadari, Technical Head, Trouw Nutrition India

Feed still accounts for 70-75% of livestock production costs, with tendency for the percentage to shoot up, due to volatility in raw material prices (as with recent skyrocketing soybean meal prices), quality and availability. In this scenario, the feed so produced, should ensure that it is safe enough for the animals consuming it as well as that the animal produce i.e., meat, milk, eggs etc., is safe for the end consumer to enable a “safe farm to fork” concept. Good quality raw materials monitored through strict quality control measures is a requisite for safe feed production. However, feed safety encompasses various aspects other than raw materials’ quality, and a holistic approach needs to be adopted to achieve the same. Feed safety should be practiced across the value chain starting from the raw material producer/trader till the processed food, as depicted in Fig. 1,

Fig. 1: Feed Safety across the value chain

From a feed mill and animal production system perspective, the below mentioned aspects need to be taken care of in a comprehensive way, to achieve feed safety,

- Microbial risk management

- Mycotoxin risk management

- Moisture management

- Feed Mill Hygiene

- Protection against oxidation

Microbial Risk Management:

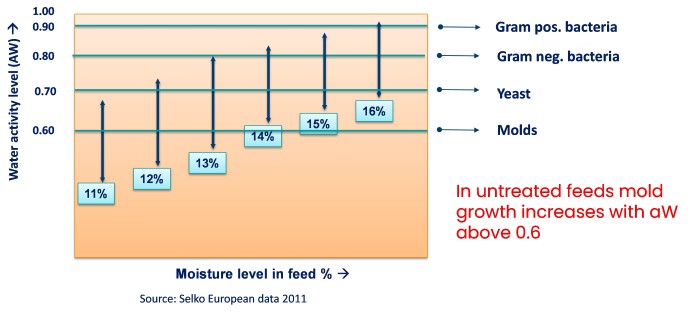

Pathogenic microbes include both the mould and bacteria, that could emanate from the raw material and/or finished feed. Moulds are difficult to address when compared to bacteria, as they are quite resistant to harsh environmental conditions (like high temperature etc.). Water activity (aW) is an essential parameter to be measured that influences microbial development, along with other parameters like temperature, humidity, exposure to light, air. aW is a measure of the amount of free water available in raw material or feed, that predisposes the material to microbial growth. Also, aW is a critical parameter to be given emphasis as against the traditional moisture measurement, which may not give a direct correlation of microbial development, as shown in Fig. 2. A water activity of 0.6 and above is suggestive of microbial growth.

Fig. 2: Relation between Water activity and microbial development

The mould and bacterial growth can be addressed through strict QC measures for procurement of quality raw materials, apt storage of raw materials and finished feed, and last but not least – judicious inclusion of mould inhibitors and feed acidifiers. The feed acidifiers intended to be used should possess specific activity against moulds or bacteria, depending upon the pathogen to be taken care of.

Mycotoxin Risk Management:

Mycotoxins are almost ubiquitous in nature and need to be handled in an integrated way considering various factors like land, crop, harvest, raw material, logistics, storage management etc. (Fig. 3). The key with respect to mycotoxin management lies in quick and accurate identification and quantification of the mycotoxin present, its risk assessment for the species involved and usage of superior quality mycotoxin binders.

Fig. 3: Factors affecting mycotoxin occurrence

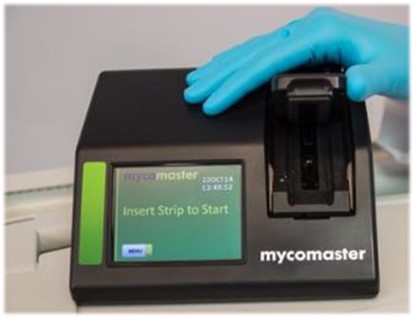

A rapid mycotoxin monitoring tool will allow producers to take quick decisions with respect to the handling of mycotoxin contaminated raw materials and/or finished feed. Trouw Nutrition has developed calibrations capable of detecting mycotoxins in a variety of raw materials and finished feed, through a tool known as “Mycomaster” – Fig. 4.

Fig. 4: Rapid mycotoxin monitoring tool - Mycomaster

Mycotoxin binders need to be added according to the prevalence, presence, and risk category (low, medium & high risk) which are specific to mycotoxin binding with little/no nutrient binding and capable of enhancing the gut health status and immunity of birds, as the latter two are compromised to a greater extent in multi-mycotoxin challenge.

Moisture Management:

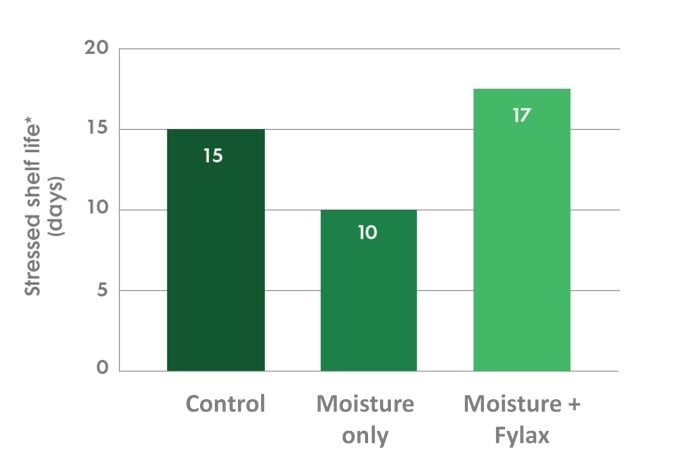

The feed moisture is dictated to a larger extent by the incoming raw material moisture and feed mill production processes. Feed moisture should neither be too low nor too high, which can lead to feed rejections and microbial risk, respectively. Too low a feed moisture can be addressed through moisture management concepts which involves addition of organic acid based liquid products coupled with surfactant and sprayed along with water onto mixer. Usage of apt quantity and type of surfactant assures that the free water is converted to bound water, so that it minimizes the risk of microbial growth due to inclusion of water from an external source. Organic acid combinations, safeguard the keeping quality of feed, ensuring its safety, owing to their antimicrobial action. Too high a moisture in feed, can promote microbial growth, which can be negated through usage of either liquid or powder mould inhibitors in the feed. Addition of water alone, as a sole source to enhance feed moisture, should never be resorted to, as it can deteriorate the feed quality instead, as charted out in Fig. 5.

As the final moisture of feed, plays a key role, in microbial risk and thereby the shelf life of feed, feed shelf-life measurements should be used as a reliable indicator of feed quality rather than the conventional microbiological assessments.

Fig. 5: Reduction in shelf life due to addition of water alone

Feed Mill Hygiene:

The cleanliness of the feed mill production processes and the premises of feed mill are an essential pre-requisite to safe feed production. Good quality raw materials and their apt storage may carry no value if feed mill hygiene is not practiced adequately. Feed mill machinery can act as strong carriers of microbial organisms and need to be effectively handled to avoid the same. Flushing of feed mill as part of maintenance program, needs to be carried out, with organic acid-based concepts, so that the production machinery is devoid of pathogenic microbes. Samples need to be collected from critical control points before and after flushing, for factual judgement of the decreased risk of (re)contamination.

Protection against oxidation:

Fats and oils are highly susceptible to oxidation and should be protected with adequate antioxidants, similarly the feed if proposed to be stored for longer durations, should be included with feed antioxidants; to enhance/maintain the nutritive value of raw material/feed.

Conclusion:

Feed safety is a broad entity by itself, and various aspects need to be considered to fulfill the objective. Various other undesirable contaminants, other than the ones mentioned above, like pesticides, heavy metals, dioxins etc. also need to be monitored to achieve safe feed. Rapid and accurate on-farm/field assays need to be available, to allow quick decisions with respect to safety and quality of raw materials and/or feed. Failing to accomplish feed safety, can cause serious concerns with respect to feed recalls, monetary losses to raw material producer, quality raw material supply chain, consequently deteriorating the animal health and performance; and the end product (meat, milk & eggs).

Trouw Nutrition boasts of a robust feed safety program that provides solution to most of the challenges faced by producers and provides a customized solution in the form of concepts, services, and products, to be used according to the situation.

To know more about how Trouw Nutrition can support you in Feed Safety Programme, kindly get in touch with your local Trouw Nutrition representative or contact us at customercareindia@trouwnutrition.com.