Prevention of Heat Stress in Poultry

- Innovation

By Dr. Sanket Wakchaure, Nutritionist, Trouw Nutrition India

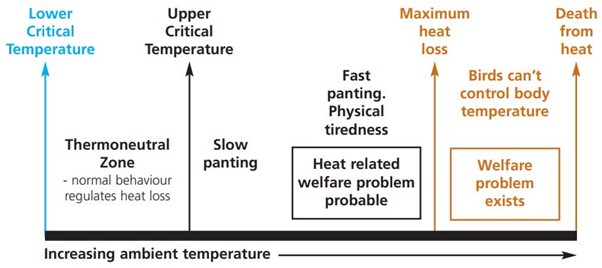

Heat stress is a major challenge in poultry production, especially during the summer months. It occurs when birds face difficulty in achieving a balance between body heat produced and heat lost. This imbalance can lead to several health issues and production losses. Therefore, it is crucial to understand the causes and responses of birds to heat stress and implement appropriate mitigation strategies to minimize the adverse impact on production.

There are several causes for heat production apart from the environmental heat. Some of them notably are higher feed intake, higher density feed and/or overcrowding of birds in a limited space, etc.

Heat stress response to maintain normal body temperature-

- Increased panting

- Spreading of wings

- Moving toward shades or towards the place where airflow is more

- Blood-swollen wattles and comb

- Diverting blood from internal organ to the skin which darkens skin colour

- Reduced physical activity

- Lesser feed intake and drinks more water which can cause loose droppings

Impact on poultry production

Heat stress production losses depend on multiple factors like maximum temperature, duration of high temperatures, rate of temperature change, and relative humidity of the air leading to the following impacts -

⬆ Mortality ⬇ Feed intake

⬇ Gut health ⬆ CFCR

⬇ Body weight ⬇ Meat quality

⬇ Immunity ⬇ Egg production

⬇ Egg weight ⬇ Egg shell quality

⬇ Albumin height ⬇ Hatchability

Impact of heat stress on Egg shell quality

Panting due to heat stress can cause an acid-base imbalance in the blood of layers, resulting in thinner and weaker eggshell. Hyperventilation in birds to regulate body temperature leads to excessive loss of CO2 gas from the lungs and blood, resulting in an increase in blood pH or a shift towards alkalinity, a condition referred to as respiratory alkalosis. A rise in blood pH levels reduces the activity of carbonic anhydrase enzyme, causing a decrease in the transfer of calcium and carbonate ions from the blood to the shell gland. The addition of calcium to the diet alone cannot rectify this issue. A reduction in feed intake and an increase in phosphorus loss leads to a decrease in calcium consumption, which is another factor contributing to thin eggshells. To restore acid-base balance, use of potassium chloride, ammonium chloride, or sodium bicarbonate is recommended.

General guide to the reaction of adult poultry to various temperatures

|

55 to 75 ⁰F

|

Thermal neutral zone. the temperature range where a bird can maintain its body temperature without any need to modify its basic metabolic rate or behavior. |

|

65 to 75 ⁰F |

Ideal temperature range. |

|

75 to 85 ⁰F |

A slight reduction in feed consumption can be expected, but if nutrient intake is adequate, production efficiency is good. Egg size could potentially decrease, and the quality of the eggshell may deteriorate when temperatures approach the upper limit of this range. |

|

85 to 90 ⁰F |

Feed consumption falls further. Weight gains are lower. Egg size and shell quality tend to decline. Egg production usually suffers. It is recommended to implement cooling measures prior to reaching this temperature range. |

|

90 to 95 ⁰F |

Feed consumption continues to drop. There is some danger of heat prostration among layers, especially the heavier birds and those in full production. At these temperatures, cooling procedures must be carried out. |

|

95 to 100 ⁰F |

Heat prostration is probable. Emergency measures may be needed. Egg production and feed consumption are severely reduced. Water consumption is very high |

|

Over 100 ⁰F |

At these temperatures, the priority is the survival of birds, and as such, urgent measures must be taken to cool them |

Fig.1 - Diagram of Thermoneutral Zone

Strategies to reduce heat stress in poultry

Heat stress reduction in poultry can be achieved by implementing various strategies. Two key strategies are housing management and nutritional management. Housing management involves adjusting the environment in which the birds are kept, including ventilation, temperature control, and lighting. Nutritional management involves providing birds with a balanced diet that includes specific nutrients that can help them cope with heat stress. Both strategies can be effective in reducing heat stress and maintaining performance. Monitoring the temperature and humidity at farm is a critical task during implementation of heat stress mitigation strategies.

1. Housing management

- Need to manage routine work and management practice schedule so that birds won’t disturb in hotter period of day

- Reduce the intensity of light in hot period to decrease physical activity of birds.

- Reschedule lightning program to make more morning light hours and less afternoon light hours to increase feed intake.

- Growing trees on both side of shed as well as covering of roof with Agri waste, dry coconut leaves or whitewash helps to reduce temperature.

- Installation of water tank inside the shed is preferable but if water tank outside the shed, then pandhal and whitewash for water tank required.

- Wet gunny on the side mesh to cool down the surrounding environment.

- Sprinkler on the roof and Foggers inside the shed, whereas usage should be limited in case of high humidity in the air.

- Fans & foggers start before 1 hour of heat increment and stop 30 minutes after panting stops. Run the foggers for 2 minutes every 20 minutes.

- Clean drinkers & flush out water from pipeline frequently in nipple system. Additionally, maintaining the appropriate height, pressure, and water flow (> 70 ml/minute/nipple drinker) of the nipples is also crucial.

- Water pipeline should be covered with gunny bag or Agri waste, underground pipeline is desirable during farmhouse construction.

- Increasing space to avoid overcrowding of birds or Removing 20 to 30 % birds after 30 days in broiler to avoid heat stress mortality in birds having higher body weight.

2. Nutritional Management

- Feed distribution at early morning & evening time (Cool part of the day) to increase the feed intake. Normally 1/3 part of feed in early morning and 2/3 part in evening to maintain eggshell quality.

- Feed intake can be increased by wet mash feeding and crumble or pellet type feed with the addition of fat or molasses to increase palatability.

- Mash feed is preferred in broiler during extreme heat stress if feed is offered ad-libitum and removal of feed is not possible to prevent mortality in higher age of production cycle (age >30 days)

- Withdrawal of feed (9 am to 4:30 pm) before anticipated time of peak temperature.

- Feed should be made denser with nutrients, vitamins, and minerals to compensate for reduced feed intake.

- Usage of vegetable or highly digestible protein sources in feed is recommended.

- Formulate to digestible amino acid targets and do not apply a high crude protein minimum in the formula. Incorporation of Synthetic amino acids can reduce crude protein in the diet without limiting amino acid levels.

- Usage of Fats or oils with more saturated fatty acids are crucial to adjust feed energy concentration rather than carbohydrate or proteins, to compensate the reduced energy intake due to less feed intake during the hotter periods.

- Oils content Linoleic acid which enhances performance and egg weights as well as oil increases palatability of feed and generates less body heat as compared to carbohydrates and protein sources.

- C and Vit. E are useful in diet because of their anti-heat stress/antioxidant properties. Inclusion Level of these vitamins in the feed can be increased in summer to improve immunity.

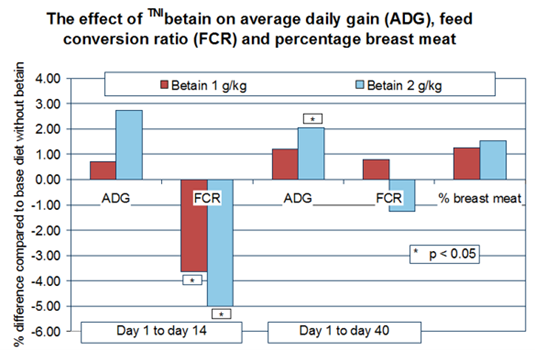

- Betaine helps in water retention, increased anabolic activity, maintained integrity of cells during heat stress condition. Additionally, betaine enhances production performance by supplying methyl group as shown in Fig. 2.

Fig. 2 - Effect of betaine on broiler performance

- Availability of cool water with increased number of waterers in which electrolytes (Potassium chloride, ammonium chloride or sodium bicarbonate) and ice cube prepared from chlorinated water can be added.

- Summer layer diet should have <250 mEq/kg dietary electrolyte balance (molar equivalence of Na+ + K+ – Cl-), whereas broiler diet like pre-starter, starter and finisher should have DEB values less than 220, 200 and 180 mEq/kg respectively.

- Use of Maduramycin as an anticoccidials in summer helps to increase water intake, whereas Nicarbazine and Monensin have negative impact.

- Mineral excretion increases during summer that’s why mineral premix dose need to increase 1.25% in feed formulation.

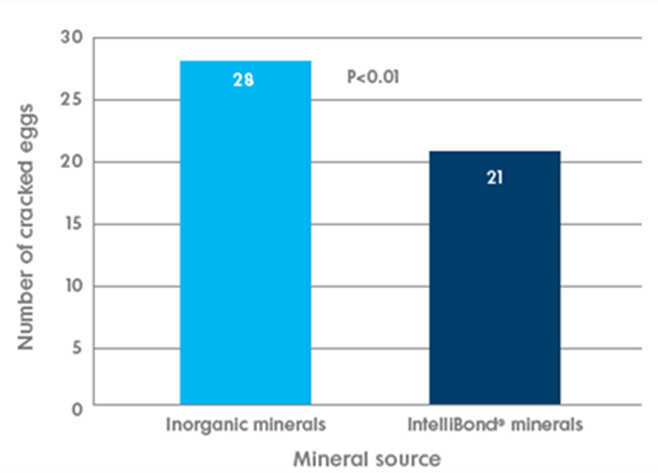

- Inclusion of hydroxy trace minerals like Intellibond to improve egg production and reduce cracked eggs.

- Supplementation of IntelliOpt, an optimal combination of hydroxy (Intellibond) and chelated (Optimin) trace mineral technology, at appropriate inclusion levels, has proved to enhance poultry performance in heat stress conditions as shown in Fig. 3.

Fig. 3 - Effect of Intellibonds on eggshell quality parameters

Preventive treatment for heat stress through drinking water:

- During moderate hot weather - ascorbic acid (Vit C) 62.5 mg/L+ acetylsalicylic acid 62.5 mg/L + sodium bicarbonates 75 mg/L + potassium chloride 125 mg/L

- In heat stress- ascorbic acid (Vit C) 400 mg/ L + electrolytes + acetyl salicylic acid (disprin 1 tablet/5 L) + sodium bicarbonate 1gm/L

Conclusion

Heat stress is a major challenge in poultry production, which can lead to several health issues and production losses. Therefore, it is crucial to understand the causes and responses of birds to heat stress and implement appropriate mitigating strategies to minimize the adverse impact on production. Effective housing and nutritional management strategies can help reduce heat stress and improve poultry performance.

For further information, kindly write to us at customercareindia@trouwnutrition.com or visit our website: www.trouwnutrition.in