Effective Strategies for Moisture Management, Mould Control and Shelf-Life Extension in Animal Feed

- Feed Safety

By Dr. Stuti Baruah, Program Manager – Feed Safety, Trouw Nutrition South Asia

Globally, feed manufacturers are facing challenges in managing feeds’ nutritional value, moisture profile, quality, shelf life and marketplace economics. Managing water content in feeds keeping in mind the climatic challenges, variability in raw material quality and technical constraints also remains a big concern. Approximately 0.5 % - 0.6 % accounts to process loss itself in cost estimations.

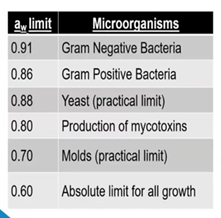

Moisture management comprises of monitoring certain parameters. First parameter is the moisture content which measures the total amount of water contained in a substance, usually expressed as a percentage of the total weight (%). Feed manufacturers track the moisture contents of raw materials, mash feed, and pellets during all processing stages to optimize quality, yields, and profitability. For curbing mould growth, another indicator is even more critical: water activity (aw) which is defined as the ratio of partial vapour pressure of water in a substance to the partial vapour pressure of pure water under the same temperature and pressure conditions. Basically, it is the energy state of water in a substance, i.e., its potential for (bio)chemical activity, including the growth of bacteria, yeasts, and moulds. Lesser the water activity (aW), better the feed quality and lesser chances of microbial growth.

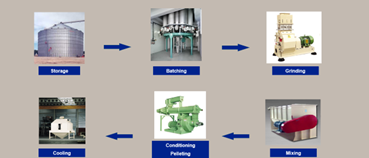

Feed Mill Flow Diagram:

Major factor that influences the pelleting process / pellet quality:

|

Factors Influencing Pellet Quality |

% |

|

Machine |

15-20 |

|

Cooling |

5-10 |

|

Formulation |

40-50 |

|

Preparation |

15-20 |

|

Conditioning |

15-20 |

Conditioning plays a crucial role in pellet /feed quality. Moisture management and mould control programs can be implemented in this phase for effective strategies of maintaining feed quality.

Feed moisture management: A common solution to compensate moisture loss is the addition of water in the form of steam during conditioning. The addition of steam aids to gelatinization, which plays an important role in throughput at the pelletizer press. However, the increased levels of moisture also pose a risk for mould growth. When not implemented correctly, moisture management can even negatively impact feed quality as it can result in reduced starch and protein content, while microbial growth and mycotoxins be a threat to animal health and performance. Additionally, it can lead to process losses, such as decreased pellet durability and reduced throughput. Moreover, process moisture loss also known as 'shrinkage' may lead to additional financial strain for the commercial feed millers. Feed moisture can be profitably managed using a synergistic blend of organic acids, as well as surfactants. This can significantly reduce press resistance and energy consumption, decreasing the risk of feed blockages at the pelletizer without increasing the risk of microbial growth during feed storage. A blend of buffered and non-buffered organic acids combined with surfactants and emulsifiers can be used to guarantee reduction, increase in milling efficiency, nutrient value preservation and feed shelf-life prolongation. This solution has been proven successful in multiple commercial situations. Also, it ensures optimum water activity ( Aw) in finished feeds.

Microbial growth is determined by water activity

Fig: Water activity & Mould /Microorganism

Surface tension reduction:

Adding solely water to the feed mash into the conditioner of a pelleting line may cause an unequal feed-mix which leads to imbalanced moisture distribution, lump formations or clogging, ultimately affecting feed quality in terms of balanced nutrient bioavailability, texture, palatability, and shelf life. Moisture distribution balancing in feed mash can be supported by increasing the droplets' surface area through reducing its cohesive forces and surface tension, thereby increasing its absorbance by ground feed particles. Thus, lowering the surface tension of steamed water droplets into the conditioner reduces the challenge of insufficient moisture absorption in feed.

Moisture distribution balancing in feed mash can be supported by increasing the droplets ‘surface area through reducing its cohesive forces and surface tension, thereby increasing its absorbance by ground feed particles. Thus, lowering the surface tension of steamed water droplets into the conditioner reduces the challenge of insufficient moisture absorption by feed mash particles during feed processing.

Mould Control and Shelf-Life Extension:

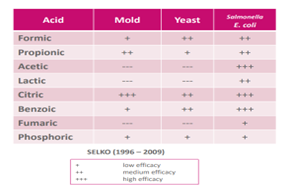

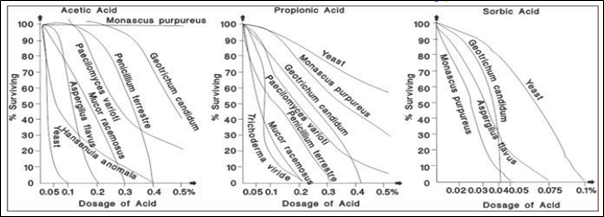

Propionic acids have been used for last 40 years as a mould inhibitor and shelf-life extension. However,, it is very corrosive, and research proves that blend of organic acids have broader spectrum of anti-microbial activity than just propionic acid.

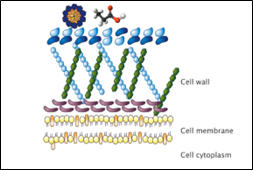

External factors, such as high temperatures combined with high humidity, as well as their fluctuations between day and night pose ideal conditions for microbes to proliferate and degrade the quality of nutrients in compound feed. To maintain the feeds' shelf life despite water addition, the application of mould inhibitors is imperative. Blending of organic acids, emulsifiers, phytochemicals are found to be most efficient mould inhibitor with ActiProp technology. This technology contains organic acid, buffering agent, surfactant, and a phytochemical. Since feed raw materials are often contaminated with several mould species, a combination of organic acids is more efficient than mould inhibitors consisting of a single organic acid. ActiProp enables acids to be more efficient in penetrating the moulds’ cytoplasm to dissociate, thereby reducing the moulds’ pH-environment into suboptimal conditions and lead to cell death.

Broad spectrum anti-microbial activities by blend of organic acids (Selko Internal Data 1996-2009)

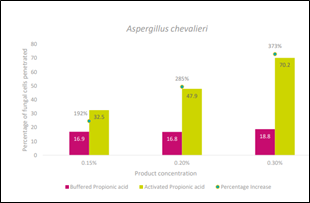

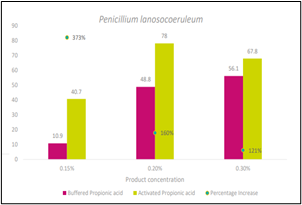

Validation is an essential step in evaluating the efficacy of solutions designed to support safety at the mill. Research conducted with Wester Dijk Fungal Biodiversity Institute, explored the individual use of buffered propionic acid, an emulsifier and phytochemical blend and ActiProp compound against Aspergillus chevalieri and Penicillium lanosocoeruleum.

ActiProp acid is 2-3 times more effective than buffered propionic acid

Source: Wester Dijk Fungal Biodiversity Institute

The activated propionates help in increasing the porosity of the mold/fungal cells by :

- Superior mould inhibition and milling performance through activated propionate. Increased porosity of cell-wall

- Destabilization of the cell membrane

- Better accessibility of organic acids

- Decrease internal pH à inhibition of growth à killing mold.

Microbiological status of feed assessed:

Measuring risk is an important step in safeguarding feed safety. Measuring Colony Forming unit (CFU) of feed is one of the measures used to assess the microbiological load in feed. Measuring CFU is the most precise and reliable approach. It is important because microbial load can directly affect the nutritional parameters of raw materials and the feed quality.

Table -Effect of moulds in nutrient profile of raw materials.CP ( crude protein )% and fat %

|

Quality reference for feed & feed raw materials |

||

|

Enterobacteria (cfu/g) * |

Molds (cfu/g) * |

|

|

Excellent |

< 10 |

< 1,000 |

|

Very good |

10 – 100 |

1,000 – 5,000 |

|

Good |

100 – 1,000 |

5,000 – 50,000 |

|

Average |

1,000 - 5,000 |

50,000 – 500,000 |

|

Poor |

5,000 – 50,000 |

500,000 – 1,000,000 |

|

Problematic |

> 50,000 |

> 1,000,000 |

Fig: Quality references for microbial feed contamination

To ensure good quality feed and optimum performance in animals, it is important to adhere to the quality reference for feed and feed raw materials.

Pellet Durability Index:

The pellet durability index (PDI) is the difference between pellet weight before and after the test recorded as a percentage.

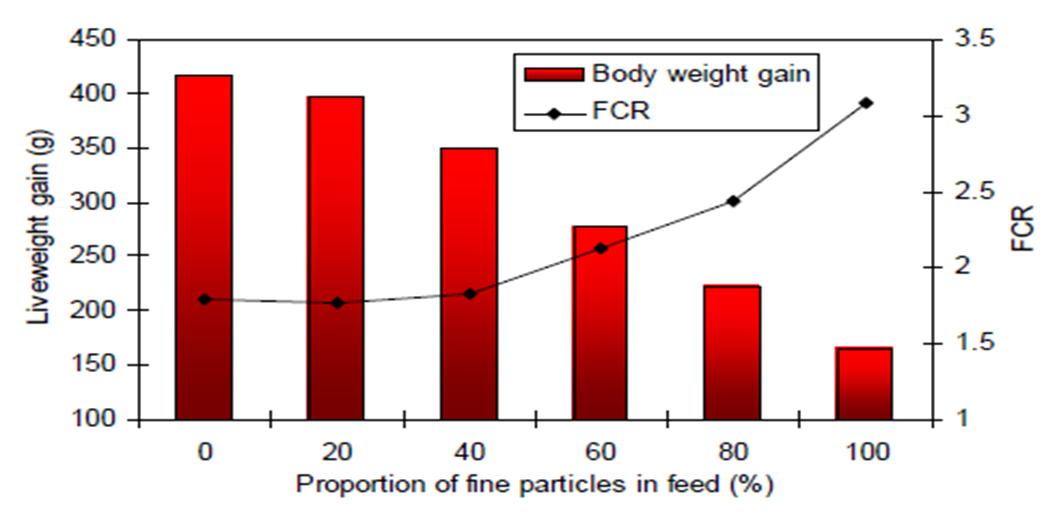

The body weight gain and proportion of fine particles in feed are inversely proportional. More the fine %, less is the body weight gain, and more is the FCR. Hence, it is important to have a good PDI.

Fig: Pellet quality- reducing fines versus broiler performance(Source: Quentin et al., 2004)

PDI was higher in blend of organic acids with ActiProp technology feed as compared to only propionic acid treated feed. Better PDI means less fines, optimum nutrient availability and lower FCR.

Table: The effects of Moisture Management program on PDI

|

Sample |

PDI (%) |

|

Propionic acid |

58 |

|

ActiProp |

69.4 |

|

|

|

PDI improvements: The pellet durability index (PDI) is the difference between pellet weight before and after the test recorded as a percentage.

‘1 Holmen unit improvement in pellet quality= 200 kg less dust per truck’(200 kgs/16 MT truck)

Operational Costs of Feed Mill

As rising gas and electricity costs pressure feed mill profitability in many markets, feed compounders are looking to maintain maximum feed plant capacity, lower the total costs of ownership of their processing plants, and optimize use of resources to secure their businesses. Use of organic acids and surfactants can doubly help save operational costs of feed production by increasing the throughput and reducing electricity consumption and effective mould control as well as enhance feed quality in terms of less fines, better PDI etc.

Stepping Up the Feed Milling Process:

Achieving optimal moisture levels in compound feed involves complex balancing between technical constraints, raw material variability, microbial challenges, and the price pressures of competitive feed markets. Blend of organic acids, surfactants, phytochemicals and ActiProp technology helps in ensuring feed mill efficiency and mould control enhancing shelf life, better PDI. To summarize from an economic point of view, the improved surfactant activity enhances the mill performance levels by increasing throughput, lower electricity use. From a feed quality angle, effective mould prevention and improved pellet quality allows for safer, more palatable feed with better FCR and bird performance thereby ensuring feed mill efficiency with effective moisture management program with emphasis on feed safety by mould control.

References: Trouw Nutrition India Pvt ltd trials/Selko Internal Trials

For further information, kindly write to us at customercareindia@trouwnutrition.com or visit our website: www.trouwnutrition.in