Optimum Moisture Management in Animal Feed

Kadhiravan Kaliyaperumal, Ashok Rajguru and Sabiha Kadari – Technical Team, Trouw Nutrition India

The goal of animal feed producers is to achieve good feed quality that would further lead to better nutrient utilization, animal performance with optimized resource use. When it concerns operational process of feed mill, achieving efficiency is one of the main targets. Relative to this, the challenge to maintain optimum moisture level with very limited total feed weight loss has been persistent. The use of moisture management program (MMP) in animal industry is a common practice today. MMP comprises of achieving a desired moisture in final feed produced and retaining that moisture over a certain period. This can be achieved by adding moisture along with organic acid and surfactant-based concept into the mixer. Whilst doing so, there are also several other interesting benefits besides the actual moisture content. These are feed quality, economic consequence due to retained finished feed weight, reduced energy usage in the feed mill, improving pellet die shelf-life, long lasting antifungal effect etc., coupled with an automated dosing and control system to monitor the entire process.

Feed Moisture Management:

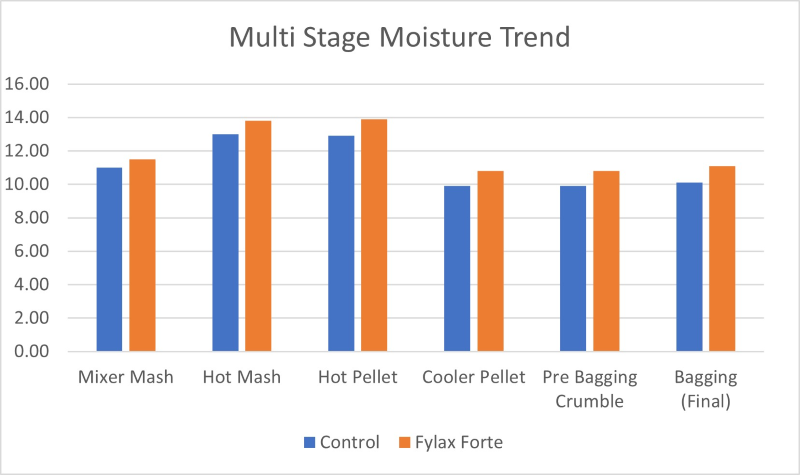

Moisture content of feed is an important indicator of weight variation that has occurred between the originally purchased raw materials and the finished products to be supplied to the market. On an average, raw materials have an average moisture content of 12%. The moisture content of raw materials drops during the process of grinding and mixing which subsequently increases during the conditioning process. The steam injection in conditioner, however, evaporates again during cooling process, as it is a saturated moisture. As a result, the moisture content of the finished product is usually between 0.5-1% lower than the initial moisture content of the raw materials. This moisture loss and the correlated uptake and retention, thereafter, can be optimized throughout the processing by adding a hydrating solution (Water +Fylax forte HC liquid) mixture to the feed, as shown in Figure 1, 2 and 3.

Figure 1: Moisture trend in various processes of feed milling

Better moisture pick-up and trend observed with Fylax Forte HC liquid supplementation.

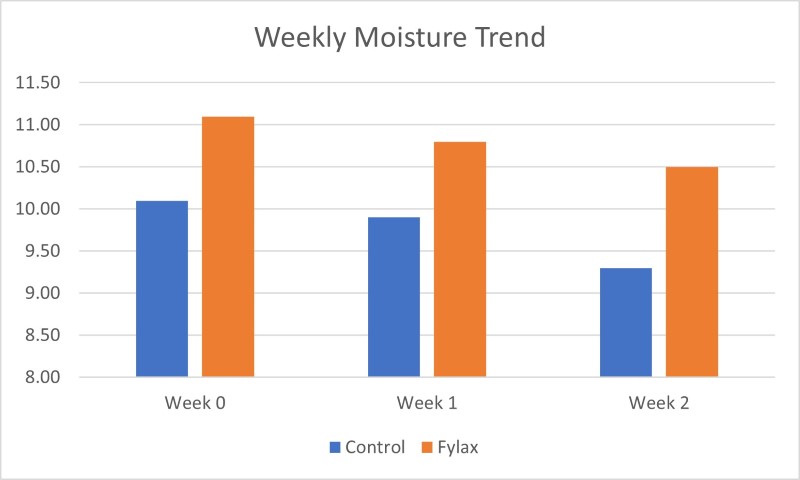

Figure 2: Moisture retention over 2-week period

Fylax Forte HC liquid was better than control in retaining moisture in feed over a period of 2 weeks.

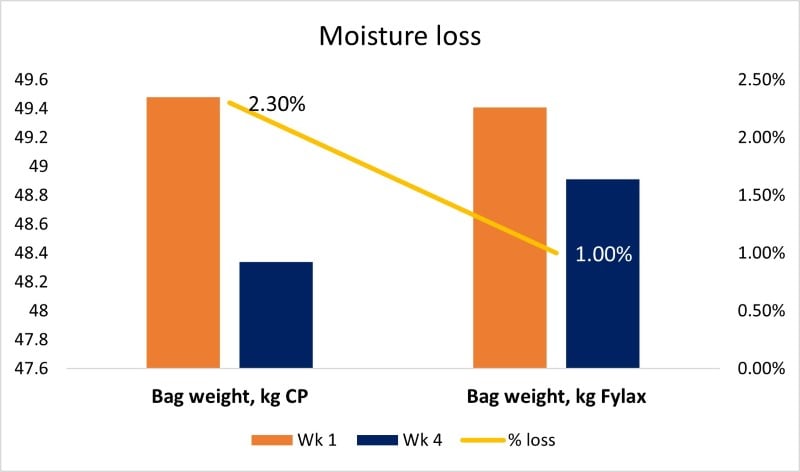

Figure 3: Moisture loss from bags stored over a period of 4 weeks

* CP – competing product

56.5% lesser weight loss of bags was observed when Fylax Forte HC liquid was used in comparison to competition over 4 weeks of feed storage.

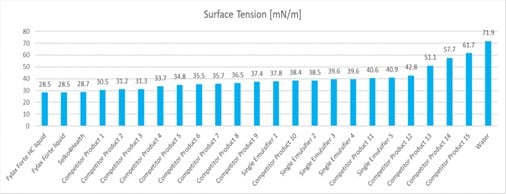

Reduction of surface tension in feed particle:

Use of Hydrating solution (Water +Fylax forte HC liquid) is an effective method to improve the moisture retention in finished feed. Surfactants are known to reduce the surface tension of water, allowing better penetration and improved distribution of organic acids, Fig. 4. The surfactant ensures that the water combined with organic acids are evenly distributed throughout the feed particle, not only remaining on the surface of the particles. The dispersion of non-corrosive, safe to handle organic acids in water enhances the quality of the final feed along with improvement in shelf life. Other advantages of adding the hydrating solution into the mixer are lubricant action in the pelletizer and related economical and energy savings. On an average, the pelletizer accounts for half the energy consumed at a feed mill. The hydrating solution (Water +Fylax forte HC liquid) leads to less friction in the die of the pelletizer which results in less energy (Amps), higher throughput and increased shelf life of pellet die. Sufficient moisture content and temperature of the conditioner using saturated steam is key in achieving gelatinization of starch by improving the hardness and durability of the pellet. Additionally, the surfactants act as a pelleting aid to improve the gelatinization during the conditioning process.

Figure 4: Comparing the surface tension with water, emulsifier, competitive liquid inhibitors against Fylax Forte HC liquid.

As depicted in Fig.4, of the various products compared, Fylax Forte HC liquid, showed the lowest surface tension.

Improvement of Feed Shelf Life:

The presence of molds in feed is a persistent problem if the feed is stored for several months under challenging circumstances due to exposure to oxygen, temperature, humidity and other handling practices. Application of mold inhibitor is crucial to maintain the shelf life of feed after inclusion of additional moisture in feed. Fylax Forte HC liquid is Trouw Nutrition’s most efficient mold inhibitor cum moisture management concept that contains apt combination of organic acids coupled with patented Technology called ActiProp. ActiProp technology enables efficient penetration of organic acids into cell wall of molds thereby enhancing the antimicrobial action. Raw materials are often contaminated with several mold species; hence a combination of organic acids is more efficient than mold inhibitors comprising of single organic acid.

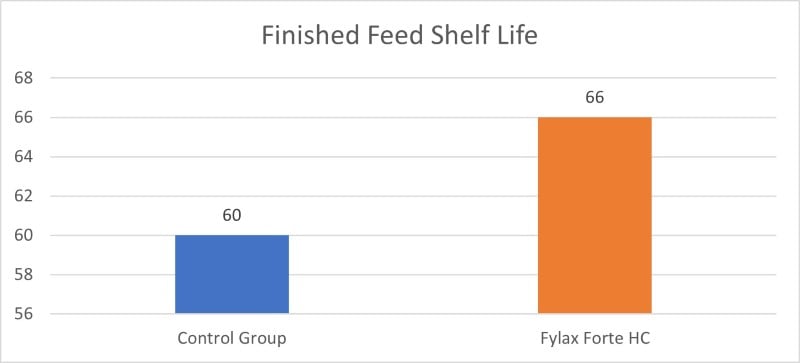

Several trials with Fylax Forte HC liquid have demonstrated improved shelf life of feed than current practices, Fig. 5.

Figure 5: Shelf life improvement with Fylax Forte HC liquid

Moisture Dosing System (MDS)

There have been desires and demands by feed millers to predict the constant dry matter recipes at 88% on average at delivery to customers. In order to meet such an expectation, a new moisture management system was developed (Fig. 6).

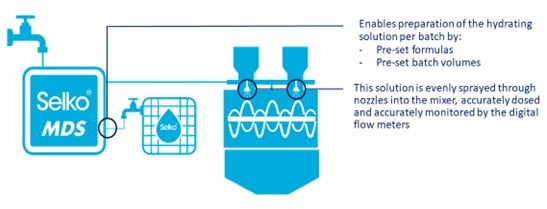

For application of the above described Hydrating Solution (Water+ Fylax Forte HC liquid), a Moisture Dosing System (MDS) needs to be used which can either automatically or manually adjust the moisture content in the feed. MDS is a PLC controlled dosing system where water is combined with a Selko Product in a pre-set ratio in an integrated tank to be used as hydrating solution, as shown in Fig. 7.

The hydrating solution is then pumped into a number of external nozzles that spray the solution over the feed inside a mixer. The MDS is especially and exclusively developed and tested in combination with Selko products and ensures that they are dosed in precise quantities.

Figure 6: Moisture Dosing System (MDS)

Figure 7: Key Characteristics of Selko MDS

Conclusion:

Moisture management and feed mill efficiency improvements has been gaining momentum in recent past. However, the user experiences have been varying and retaining the desired moisture in final feed for a certain period has been a herculean task. It requires an integrated dynamic approach that would vary from one feed mill to another depending on various external factors. Given the extensive experience of Trouw Nutrition in the area of management of added moisture, Fylax range has been introduced in India along with dosing system to help producers improve their feed mill efficiency, feed quality and shelf life with adequate microbial control consequently improving their overall productivity and profitability.

For further information, please connect with us at customercareindia@trouwnutrition.com