Challenges and solutions of feed raw material treatment under Asian conditions

- Feed Safety

Humidity and precipitation are ongoing challenges for animal feed raw materials especially during the Asian region’s annual wet season (May to October). Proper storage of raw ingredients and processed feeds is required to support feed safety, stability and quality. Trade is another consideration. Bans on corn imports in some Asian countries increases the need to maintain a high level of quality for feed raw materials. Protecting and preserving valuable nutrients supports optimal feed quality, thereby animal nutrition and growth.

by Kai-J. Kühlmann & Pieter Steyn

Storage in tropical weather

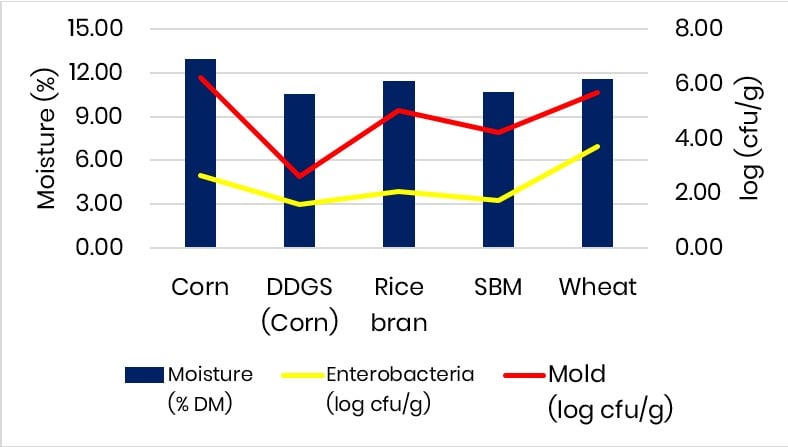

World grain and soy production are currently estimated to represent 2.5 billion tons (annually). About one third of this production is wasted [1], accounting for roughly 20% of greenhouse gases and significantly contributing to global warming [2]. Sourcing feed raw materials to produce high quality, nutritious feeds for industrially farmed animals is often challenging under tropical climate conditions. During the wet season, heavy warm rains create favourable conditions for moisture to develop. These conditions often lead to massive mould and bacteria development on the farm and the mill and during months of storage in silos, bulk or bags. Feed raw materials often reach their final moisture content during storage. As the ingredients continue to take up oxygen and exhale carbon dioxide and water (‘grain breathing’), the temperature inside the storage environment can rise. These conditions allow moisture to condensate at the inner silo walls and within the stored raw materials; especially during the cooler dry season when day-night temperatures fluctuate more widely. The storage situation creates a risk of vast mould and bacterial development nourished by the stored feed raw materials purchased, thereby degrading its quality (Figure 1).

Figure 1: Direct relation between moisture, mould and enterobacteriaceae growth on various stored feed raw materials from Asian countries (Indonesia, Myanmar, Thailand, Vietnam)

(DDGS – Dried Distillers Grains with Soluble from corn, SBM – Soybean meal)

Although grain and feed producers are highly aware of the most efficient, cost-effective storing methods is undisputed, the efficiency of feed raw material preservation is often in question. This article discusses common approaches for raw material management in Asia and offers industrial stakeholders’ guidance to preserve the high nutrient quality of feed raw materials over time so that ingredients support optimal animal feed production.

Drying

In many geographic regions, feed raw materials go through drying processes. These processes aim to lower the materials’ moisture content to reduce microbial growth of mould and bacteria during storage. Drying, used since ancient times, has evolved and changed over the decades. Sun-drying of feed raw materials is cost-effective, yet, highly dependent on the tropical daily weather, often changing fast with temperature, precipitation, and air pressure.

Pests and microbes present another concern as microbes, pests, birds or rodents can contaminate or feed on the drying raw materials. While technology such as industrial driers can mitigate challenges with sun drying, this approach requires significant volumes to justify the investments in equipment and training personnel to operate these energy consuming systems. Corn dried in Indonesia reduced its moisture content from 12.3% to 11.1% with a concomitant mould count reduction from 100,000 cfu/g to 30,000 cfu/g [3].

Aerating

Harvested or imported feed raw materials with low moisture content are usually higher in their nutritive feed quality and more expensive than raw materials containing a higher moisture content, e.g., above 15%. Although drying may not be required for feed raw materials with low moisture content, steady ventilation inside the silo is essential. Ventilation helps to avoid core condensation within the dried feed raw material. Obtaining a constant temperature over the several months’ storage period is important and temperature should not vary more than 2% within the stored volume. During the aeration process, air with lower equilibrium moisture content than the feed raw material is constantly blown and ventilated into the stored grains to keep the grains’ moisture content even and, preventing moisture migration and condensation, thereby, lowering the risk of mould and bacteria proliferation. During wet seasons and heavy tropical rains, aeration cannot be applied since higher moisture than that of the stored feed material would be blown into the silo. This situation would increase the moisture content of the feed raw materials with concomitant mould development inside the silo.

Organic acid application

The higher the initial moisture content of feed raw materials, the higher the risk of microbial contamination by moulds or bacteria prior to storage. Organic acid blends evenly sprayed onto the feed raw materials prior to storage are a useful approach to prevent microbes from consuming valuable nutrients. The organic acids penetrate bacteria or moulds and dissociate, thereby reducing the pH-value environment into sub-optimal conditions, which leads to nuclei destruction and cell death. In essence, organic acids create an inhospitable environment where harmful bacteria and moulds struggle to survive.

Common organic acid-based mould inhibitors contain buffered blends of acetic, propionic or sorbic acid formulated in varying concentrations. These organic acids are selected to reduce the pH-environments of several mould species during the feed raw materials’ storage time. The market solutions offered are abundant and often, a farmers’ challenge is to select the right treatment for the issues at hand. For instance, a single organic acid can be effective for certain mould species. Yet, this acid may have a narrow scope and therefore a limited impact to reduce moulds which can continue to proliferate despite the organic acid treatment. Furthermore, single organic acids or blends tend to be highly volatile. This volatility results in less efficiency over the storage period and can limit microbial protection of feed materials, thus presenting a recontamination risk. The corrosiveness of organic acid blends poses an additional risk for the storage facility, such as a silo. Considering that the silo walls are made and hold together by different materials, once the screws or rivets corrode, silo walls can collapse with significant damage.

Complex issues require precise and comprehensive solutions

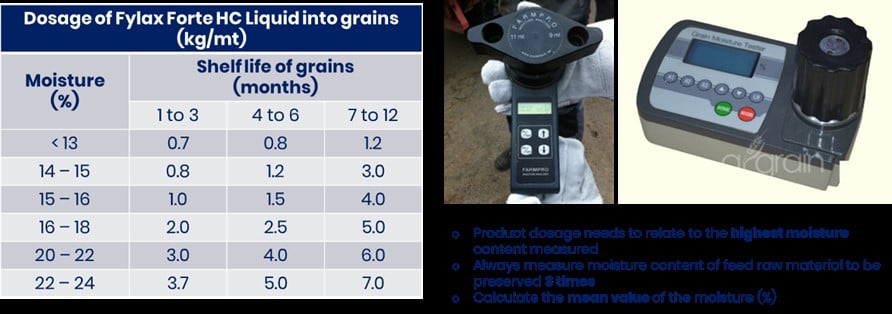

As with many challenges across the feed to food chain, there is no single solution to overcome risks associated with raw material preservation. Trouw Nutrition’s integrated Feed Safety Program offers solutions to treat feed raw materials prior to several months’ storage. The solutions include various blends of buffered and non-buffered organic acids designed to preserve the materials’ nutrient content in high quality, ready for best feed processing. Liquid organic acids are generally more efficient compared to those in powder form due to the absence of an organic acid carrier. Having determined the current moisture content of a feed raw material in combination with the storage duration anticipated (Figure 2), Trouw Nutrition’s organic mould inhibiting acid blend can be sprayed onto the feed raw material prior to silo filling. Here is a practical example of optimizing moisture while reducing mould: Treating dried corn (initial moisture content of 11.1% and a mould count of 30,000 cfu/g, [3]) with 0.8% Fylax® Forte-HC liquid increased moisture content to 11.8%, and reduced the mould count to 10,000 cfu/g. The non-corrosive organic acid blends guarantee increased shelf life compared to untreated feed raw materials. The acids also keep concomitant nutrient quality of stored feed raw materials. From an application perspective, the liquid is sprayed on with state-of-the-art programmable dosing equipment suited to fit the customer’s respective conveying belt capacities and requirements.

Figure 2: The initial moisture content of the corn (%) & anticipated storage period determines the dosage of Fylax Forte-HC liquid (kg/mt)

Part of the Trouw Nutrition Selko feed additive family, Fylax Forte-HC liquid contains patent-pending ActiProp® technology; a combination of buffered and non-buffered organic acids, surfactants, emulsifiers and plant-based materials allowing for a more intense penetration of the product into feed raw materials. By following Trouw Nutrition’s guidelines on feed raw material storage, farmers and grain processors can support farm economics by purchasing a less costly grain containing higher moisture. Through the application of Fylax Forte-HC liquid with the suitable dosing equipment, the returns on investment are significantly increased, thereby opening commercial approaches for medium-to high moisture grain treatment during silo storage (Figure 3).

Figure 3: Return on Investment (ROI*) for corn of various moisture content (%) treated with Fylax Forte-HC liquid up to 12 months

(* Reference: Thailand corn prices)

Optimizing feed raw material storage through a unique combination of market specific solutions, applicable models and customer tailored services supports Trouw Nutrition’s commitment to feed-to-food safety and contributes to a mission of ‘Feeding the Future’.

References:

[1] Shurson, GC (2020): “What a Waste”—Can We Improve Sustainability of Food Animal Production Systems by Recycling Food Waste Streams into Animal Feed in an Era of Health, Climate, and Economic Crises?. - Sustainability 2020, 12: 1-34. (doi:10.3390/su12177071)

[2] FAO (2013): Toolkit – Reducing the food wastage footprint. - http://www.fao.org/3/i3342e/i3342e.pdf

[3] Internal trial report 40: Fylax® Forte-HC liquid mould inhibition of corn in Indonesia